PRECAST WALL PANEL

- The thickness of the precast wall panels can be varied, depending on the structural engineering requirements by changing the height of the side formwork

- The size of wall panels can be adjusted in terms of both height and width to satisfy architectural requirements and functional purpose of the building

- The wall panels are cast in the specially designed mould

- The edge of the precast wall panels is cast with a shear key joint. This shear key, coupled with starter bars, provides very strong interlocking and strength after the columns have been cast

Standard Panels

All design panel wall height as per table below :-

Item |

Panel Wall Thickness (mm) |

Panel Wall Height (m) |

1 |

100 mm |

3.0 m |

|

|

3.5 m |

|

|

4.0 m |

2 |

120 mm |

3.0 m |

|

|

3.5 m |

|

|

4.0 m |

|

|

4.5 m |

3 |

150 mm / 160 mm |

4.0 m |

|

|

4.5 m |

|

|

5.0 m |

Panel thickness, breadth and height can be varied to suit project requirements. However the panel height above 3.7m must be cast at site due to the restriction of height at the highway.

COLUMNS

- Various column or joint shapes are formed as a result of the intersection of the different wall panels. The columns are formed by basically clamping the various wall panels with specially designed moulds

- Standalone columns can also be constructed with the same mould

- The column moulds consist of a series of standard module design of moulds, interlocked and assembled to form various shapes of columns required

- The size of the columns can be easily increased or reduced by increasing or reducing the number modules

- The moulds are made from aluminium to achieve the desired pattern and to make it light to handle

SLAB PANELS

The slab can be either carried out as in-situ construction of precast planks with concrete topping. It is highly recommended the toilet area to be done as in-situ construction to negate any water leakage problem.

For precast planks and with concrete topping construction :-

- The precast plank are precast in sleeping moulds

- Starter bars are left at the edges for interconnection of cast in-situ beams and columns

BEAM

STAIRCASE

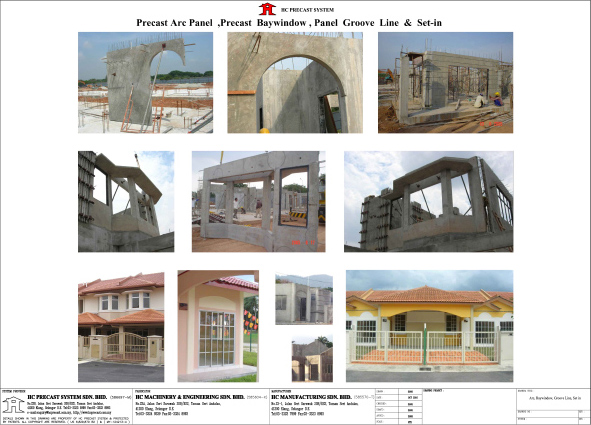

Precast Arch Panel, Precast Baywindows, Panel Groove Line and Set-in