|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

EARTHQUAKE RESISTANCE TEST OF SCALED DOWN DOUBLE STOREY BUILDING BY HC PRECAST SYSTEM IN COLLABORATION WITH UTM, JOHOR BASED ON 8 MAJOR EARTHQUAKES, IN THE WORLD

PECB Properties Berhad visited HC Precast System Sdn Bhd Rasa Factory HC Precast System Sdn Bhd is pleased to welcome all the team from PECB Properties Berhad, Architects, Consultants & Engineers to our Rasa Factory for an insightful visit to explore our innovative IBS technology. This advanced system will be implemented in PECB’s latest shoplot project at Kg. Lombong. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15-9-2018 | : | HCPS Mock-up Panel Inspected By Reputable Company From Japan |

| 12-9-2018 & 13-9-2018 |

: | HCPS Mock-up Panel For Reputable Company From Japan |

| 15-8-2018 | : | HCPS Visit By Reputable Company From Japan |

| 4-8-2018 | : | HCPS Visit By Reputable Company From Japan |

IBS Mock-up Panel Inspected By Reputable Company From Japan

IBS Mock-Up Panel Off-Site 80% - 90%

IBS Mock-Up Panel On-Site 10% - 20%

| 15-11-2019 & 16-11-2019 |

: | HC PRECAST SYSTEM MOCK-UP PANEL TEST BY REPUTABLE COMPANY FROM JAPAN AFTER 24 HOURS |

| 15-11-2019 & 16-11-2019 |

: | HC PRECAST SYSTEM MOCK-UP PANEL TEST BY REPUTABLE COMPANY FROM JAPAN |

| 25-09-2019 | : | IBS FACTORY VISIT COUNTRY GARDEN PACIFICVIEW SDN BHD |

| 23-07-2019 | : | IBS FACTORY VISIT DAYA BUILDERS SDN BHD |

HC PRECAST SYSTEM MOCK-UP PANEL TEST BY PANASONIC HOMES MKH MALAYSIA SDN BHD

- Coring Test (Between Wet Joint & Precast Panel Wall)

- 19/7/2019

“In Line With Government's Housing 4.0 Agenda For IBS For Superstructure Works”

Industrialized Building System (IBS) Superstructure Specialist

100 % Malaysia Technology With 6 IPs’

GREEN BUILDING

Unique 3 in 1 System :

- Monolithic Load Bearing Wall

- Modular Wet Joint System (Shear Keys)

- Box System

Economical . Eco Friendly . Quality . Fast . Feasible . Flexible

Customizable & Flexibility To Suit Architectural Demands

2 Units Single Storey Semi-D House

Completed in 9 Days with 9 Workers (8.00 am - 7.00 pm)

TEMERLOH - PREPARATION WORKS

Mobilisation 3 Days :

a) Site Office Setup

b) Precast elements delivery

c) Setting-out for panel installation

Day 1 of 9 ( 18/01/2019 ) :

- Ground Level Precast Wall Panel Installation & Filling Of Expanding Cement

Day 2 of 9 ( 19/01/2019 ) :

- Ground Level Expanding Cement Filling, Wet Joint Rebar, Modular Mould

Installation & Concreting

Day 3 of 9 ( 20/01/2019 ) :

- Ground Level Wet Joint Rebar & Modular Mould Installation

Day 4 of 9 ( 21/01/2019 ) :

- Car Porch Column Rebar, Modular Mould & Precast Beam Installation

- Ground Level Wet Joint & Car Porch Column Concreting

Day 5 of 9 ( 22/01/2019 ) :

- Ground Level Wet Joint Modular Mould Dismantle

- Precast Half Slab & In-situ Modular Mould Installation For RC Flat Roof At

Water Tank Area

Day 6 of 9 ( 23/01/2019 ) :

- Ground Level Wet Joint Modular Mould Dismantle

- Precast Half Slab & In-situ Modular Mould Installation For RC Flat Roof At

Car Porch

- Roof Level Precast Wall Panel Installation

Day 7 of 9 ( 24/01/2019 ) :

- Ground Level Wet Joint Modular Mould Dismantle

- Car Porch Coping Modular Mould, In-situ Slab Rebar & BRC Installation

- Roof Level Precast Wall Panel Installation

- Roof Level Wet Joint Rebar Installation

Day 8 of 9 ( 25/01/2019 ) :

- Roof Level Wet Joint Rebar & Modular Mould Installation

Day 9 of 9 ( 26/01/2019 ) : LAST DAY

- Roof Level Wet Joint Concreting

- Car Porch In-situ Flat Roof Concreting

- All Support/Prop To Beam Will Be Dismantle After 14 Days ( 09/02/2019 ) As

Comply To BSI Code

COMPLY TO BSI CODE 14 DAYS DISMANTLE

(All Support & Prop To Beam )

“ In Line With Government's Housing 4.0 Agenda For IBS For Superstructure Works ”

Industrialized Building System (IBS) Superstructure Specialist

100 % Malaysia Technology With 6 IPs’

GREEN BUILDING

Unique 3 in 1 System :

- Monolithic Load Bearing Wall

- Modular Wet Joint System (Shear Keys)

- Box System

Economical . Eco Friendly . Quality . Fast . Feasible . Flexible

Customizable & Flexibility To Suit Architectural Demands

COMPLY UBBL, BSI & BOMBA APPROVAL PROJECT

- 2 Units Single Storey Semi-D

- Completed In 9 Days With 9 Workers (8:00 am - 7:00 pm)

IN LINE WITH GOVERNMENT'S HOUSING 4.0 AGENDA FOR IBS FOR SUPERSTRUCTURE WORKS

- 2 Units Single Storey Semi-D

- Completed In 9 Days With 9 Workers (8:00 am - 7:00 pm)

Part 3 of 3 (Day 7 to Day 9)

Part 2 of 3 (Day 4 to day 6)

Part 1 of 3 (Day 0 to Day 3)

Choose Industrialised Building System (IBS) For Economical Construction Industrialised Building System (IBS) Functions As A Comprehensive Superstructure Construction System Whereby Flexibility In It's Customisation Allows Architect's Creativity To Flourish.

EUROCODE 8 FOR MALAYSIA

- Earthquake Resistant Test By HCPS In Collaboration With UTM, Johor

- Utilised BSI Code : 8 Major Earthquake In The World

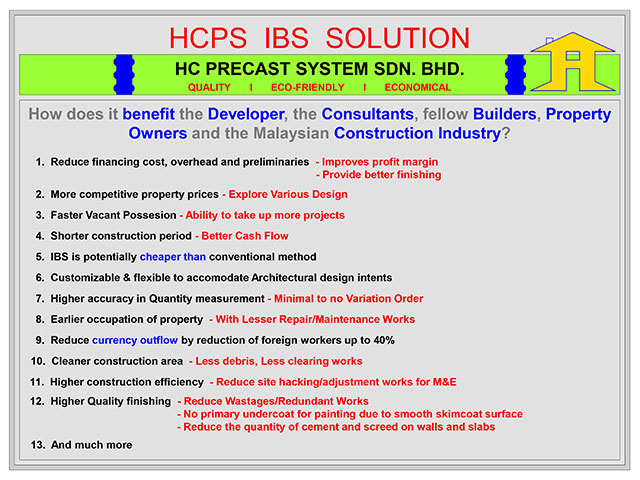

ADVANTAGE INDUSTRIALIZED BUILDING SYSTEM (IBS)

- Commercial Advantages

- Technical Advantages

SCOPES OF WORKS FOR SUPERSTRUCTURE (FRAME & WALL)

HCPS CONSTRUCTION METHOD

HCPS COST SAVING

COST COMPARISON

HC Precast System vs Conventional Method

Rate Can Be Checked & Change By You (Online) - 2018

Payment Terms

HCPS IBS CONCEPT (SEQUENCE OF WORK)

RENOVATION IN COMPLETED HCPS PROJECT

HCPS 6 IPs’, INTERNATIONALLY PUBLISHED BY FOREIGN JOURNALS AND MAGAZINES

HCPS ADDITIONAL COST SAVING

WHOSE RESPONSIBILITY !!

| 22-03-2019 | : | IBS FACTORY VISIT KERAJAAN PERSEKUTUAN SARAWAK |

https://www.facebook.com/hcprecast/videos/2291177837794070/

https://www.facebook.com/hcprecast/videos/1727528480682516/

https://www.facebook.com/hcprecast/videos/1490172691118781/

| 04-03-2019 | : | PROJECT SITE VISIT |

| 12-12-2018 | : | IBS FACTORY VISIT |

| 15-11-2018 | PANASONIC HOME MALAYSIA SDN BHD |

https://www.facebook.com/hcprecast/videos/1950675771724878/

https://www.facebook.com/hcprecast/videos/351279975722038/

| 30-12-2017 | : | FACTORY VISIT CHINA HYWAY GROUP LIMITED |

| 5-12-2017 | : | FACTORY VISIT UDA HOLDINGS BERHAD |

| 13-10-2017 | : | PRESENTATION MINISTRY OF SCIENCE, TECHNOLOGY AND INNOVATION (MOSTI) NATIONAL INNOVATION AND CREATIVE ECONOMY EXPO 2017 (NICE '17) |

| 19-09-2017 | : | PRESENTATION MINISTRY OF SCIENCE, TECHNOLOGY AND INNOVATION (MOSTI) BENGKEL DUE DILIGENCE SIRI KETIGA TAHUN PENGKOMERSIALAN MALAYSIA (MCY 2017) |

| 26-04-2017 | : | FACTORY VISIT SOUTH CHINA ARCHITECTURAL DESIGN & RESEARCH INSTITUTE (SCADRI) (POWER CHINA/PROJECT) |

| 25-04-2017 | : | OFFICE VISIT SOUTH CHINA ARCHITECTURAL DESIGN & RESEARCH INSTITUTE (SCADRI) (POWER CHINA/PROJECT) |

| 22-08-2015 | : | FACTORY VISIT MALAYSIAN RESOURCES CORPORATION BERHAD (MRCB) |

| 29-08-2016 | : | IBS FACTORY VISIT MATRIX CONCEPTS HOLDINGS BHD |

| 15-03-2017 | : | TECHNICAL AND SITE VISIT PERBADANAN KEMAJUAN NEGERI SELANGOR (PKNS) SELANGOR INDUSTRIAL CORPORATION (SIC) PKNS INFRA BERHAD (PIB) SELAMAN |

| 11-01-2017 | : | TECHNICAL AND SITE VISIT JABATAN PENILAIAN DAN PERKHIDMATAN HARTA (JPPH) GOMBAK KEMENTERIAN KEWANGAN MALAYSIA |

| 8-12-2016 | : | FACTORY VISIT JABATAN KERJA RAYA (JKR) BAHAGIAN PEMBANGUNAN DAN PENYELIDIKAN CAWANGAN KEJURUTERAAN AWAM DAN STRUKTUR |

| 8-10-2016 | : | EDUCATIONAL VISIT JABATAN SENIBINA FAKULTI SENIBINA, PERANCANGAN DAN UKUR UNIVERSITI TEKNOLOGI MARA (UiTM) PERAK |

HC PRECAST SYSTEM SDN BHD

MALAYSIA IBS TECHNOLOGY

Certificate of Publication For HC Precast System Article

LATEST SCIENTIFIC ARTICLE PUBLISHED IN MAY 2016

Scientific paper entitled Case study of load-bearing precast wall system subject to low seismic intensity by linear and nonlinear analyses is featured in "Case Studies in Structural Engineering" by Elsevier

Editor-in-Chief: Professor Kourosh Kayvani

named Top 100 most influential Engineers by Engineers Australia in 2009

Important Element Required To Complete a Building

Rate Can Be Checked & Change By You (Online)

1. Double Storey : Cost Comparison of Superstructure (Frame & Wall) - (slide 24)

2. Single Storey : Cost Comparison of Superstructure (Frame & Wall) - (slide 25)

3. Cost Comparison of Superstructure (Frame & Wall) - (slide 26)

5. Work Program - 300 Units Single Storey Terrace House - (slide 58, 59, 60)

MALAYSIA GREEN TECHNOLOGY

Industrial Building System Concept :-

- Superstructure / Frame & Wall

Rate Can Be Checked & Change By You

1. Comparison of Superstructure Frame & Wall - (slide 94)

3. Work Program 2015 - (slide 109)

INTELLECTUAL PROPERTY HC PRECAST SYSTEM

IBS IS A SYSTEM NOT A MACHINE - MOULD SETTING

INSTALLATION SEQUENCE

ONE OF THE WAYS TO IMPROVE THE OUTFLOW OF CURRENCY IS THE UTILIZATION OF INDUSTRIAL BUILDING SYSTEM (IBS)

PERUMAHAN KEKAL MANGSA BANJIR

PERUMAHAN KEKAL MANGSA BANJIR (RKB)

13/11/2014 PR1MA FACTORY VISIT

|

PR1MA group

|

PR1MA Group Arrival

Show Unit Briefing

Training Unit Briefing

Precast wall, precast staircase, precast beam, half slab & wet joint

noted: original, no touch up & open air 7 years

Production Yards Briefing

Metal Door Frame, Opening, Groove Line, Coping, Conduit & Piping

Engineering Warehouse Briefing

Live Demo Precast Beam & Staircase Mould Dismantle

1. Why IBS

| Issues | Conventional | IBS |

| Currency | Outflow | Remain in country |

| Social | High | Less |

| End Product | Low quality | High quality |

| Labour Required | High | Less |

ACHIEVEMENTS OF HC PRECAST SYSTEM SDN BHD IN 2013

Technical paper accepted for publication in "Earthquakes and Structures" (Impact Factor 2012 = 1.381, one of the highest among other structural earthquake engineering journals, indexed by Journal Citations Reports®, ISI Thomson Reuters)

Technical paper published in the Proceedings of the 15th World Conference on Earthquake Engineering (Lisbon, Portugal, 2012)

Production and Quality Control

| Production / Capacity - 2,000 - 3,000 Single Storey Terrace House / year |

Quality Control - Verticle Storage - Proper Storage Frame |

Low Investment

Temporary Factory Setup

All Type of frame

SuperStructure

Supply & Lay Precast Wall Panel with wet joint (Including Design Calculation)

|

100mmthk Precast Panel Wall for Single Storey Housing Price per m² = RM90 |

|

120mmthk Precast Panel Wall for Double Storey to 5 Storey Housing Price per m² = RM108 |

| Built-Up Area | Wall Area | Super Structure Volume | Supply & Lay Cost (Rm900 per m³) |

Video | ||||

| ft² | m² | m² | m³ | Per Unit | ||||

| Single Storey Bungalow House | 850 |

78.97 | 157.00 | 15.70 | 14,130.00 |

|||

| 940 | 87.30 | 206.40 | 21.00 | 18,900.00 | ||||

| 1200 | 111.48 | 211.50 | 21.15 | 19,035.00 | ||||

| 1500 | 139.35 | 215.00 | 21.50 | 19,350.00 | ||||

| 1800 | 167.23 | 272.00 | 27.20 | 24,480.00 | ||||

| Double Storey Semi-Detached | 2698 | 250.67 | 714.20 | 171.90 | 154,710.00 | |||

|

Corner Unit | 1690 | 157.00 | 245.41 | 47.00 | 42,300.00 | ||

| Inter mediate | 1640 | 152.36 | 219.75 | 44.29 | 39,861.00 | |||

| End Unit | 1680 |

156.07 | 245.25 | 46.00 | 41,400.00 | |||

| Double Storey Terrace House | Corner Unit | 2520 | 234.11 | 351.91 | 53.92 | 48,528.00 | ||

| Inter mediate | 2370 | 220.17 | 333.00 | 51.52 | 46,368.00 | |||

| End Unit | 2510 | 233.18 | 357.58 | 54.60 | 49,140.00 | |||

| Double Storey Terrace House | Type A | 2000 | 185.80 | 365.42 | 55.28 | 49,752.00 | ||

| Type B | 2330 | 216.46 | 398.83 | 61.75 | 55,575.00 | |||

| 4 -Storey Quarter | 12227 | 1135.96 | 1974.43 | 489.53 | 440,577.00 | |||

| 5- Storey Quarter |

35668 | 3313.64 | 4155.92 | 1005.79 | 905,211.00 | |||

- HC's Greatest Achievement

ACHIEVEMENTS OF HC PRECAST SYSTEM SDN BHD IN 2012

Actual Photo Actual PhotoConcrete Volume = 1.618m³ Area = 13.92m² |

Coming soon actual product Coming soon actual productConcrete Volume = 3.76m³ Area = 31.423m² |

TO SUPPLY & LAY 120mm thk Precast Panel(Double Storey) = RM108.04/ m²

TO SUPPLY & LAY 100mm thk Precast Panel (Single Storey) = RM90/ m²

* NOTE : RM900/m³ (subject to term & conditions)

- HC Precast System: Scope of Works For Superstructure

Included:

- Superstructure design calculation.

- Supply & install.

- Setting out (panel) : TBM for each block & 4 Boundary point per unit must be provided.

- Mobile crane.

- Shop drawing for M&E location layout related to panel wall casting. (Subject to client/consultant confirmation)

Excluded:

- Substructure design by others.

- Supply & install metal door & window frame.

- Supply & install M&E conduit.

- Skim cost.

- Storage yard at project site : 50mm thick crusher run base.

- Access road at project site.

- Temporary water & electricity supply.

- Quarters for workers.

*** Person In charge

| 1) | En. Fadzil b. Ahmad Tel : 03-3323 3993 ext 302 Fax : 03-3324 3993 Email : fadzil35@gmail.com |

2) | Mr. Choo Tak Min Tel : 03-3323 3993 ext 307 Fax : 03-3324 3993 Email : enquiry@hcprecast.com |

3) | Ms. Wong Suat Nee Tel : 03-3323 3993 ext 306 Fax : 03-3324 3993 Email : enquiry@hcprecast.com |

| ITEM | BENEFIT | DESCRIPTION | CONVENTIONAL | IBC | IBS |

| 1 | Country | Currency | -40% | ? | +40% |

| 2 | Sosial Issues | +40% | ? | -40% | |

| 3 | Developer & End User | Suit to Architect Designs | Yes | ? | Yes |

| 4 | Speed | 24 months | ? | 14 months | |

| 5 | Quality | Poor | Medium | High Quality | |

| 6 | Maintenance | High Maintenance | ? | No Maintenance | |

| 7 | Responsibility | Responsibility by design's engineer | ? | Full responsibility by system provider & design engineer | |

| 8 | Renovation | 2D | 2D | 3D, M&E Drawing details & SOP | |

| 9 | Crack | Yes | ? | Minor | |

| 10 | Leakage | Yes | ? | No | |

| 11 | Production delivery control | Site Arrangement Messy | ? | Arrange by system provider | |

| 12 | Construciton site | Messy | ? | Neat |

One of the very first Malaysian IBS Company presenting academic poster at the 15th World Conference on Earthquake Engineering in Lisbon, Portugal 24-28th Sep 2012

ACHIEVEMENTS OF HC PRECAST SYSTEM SDN BHD IN 2011

| Costing | |||||||||

| Time Frame | |||||||||

| Brochures | |||||||||

| Video | |||||||||

| Interior Design | |||||||||

|

|||||||||

-&-2-units(Temerloh)-drawings.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-1-18072019.jpg)

-280818.jpg)

-280818.jpg)

.jpg)